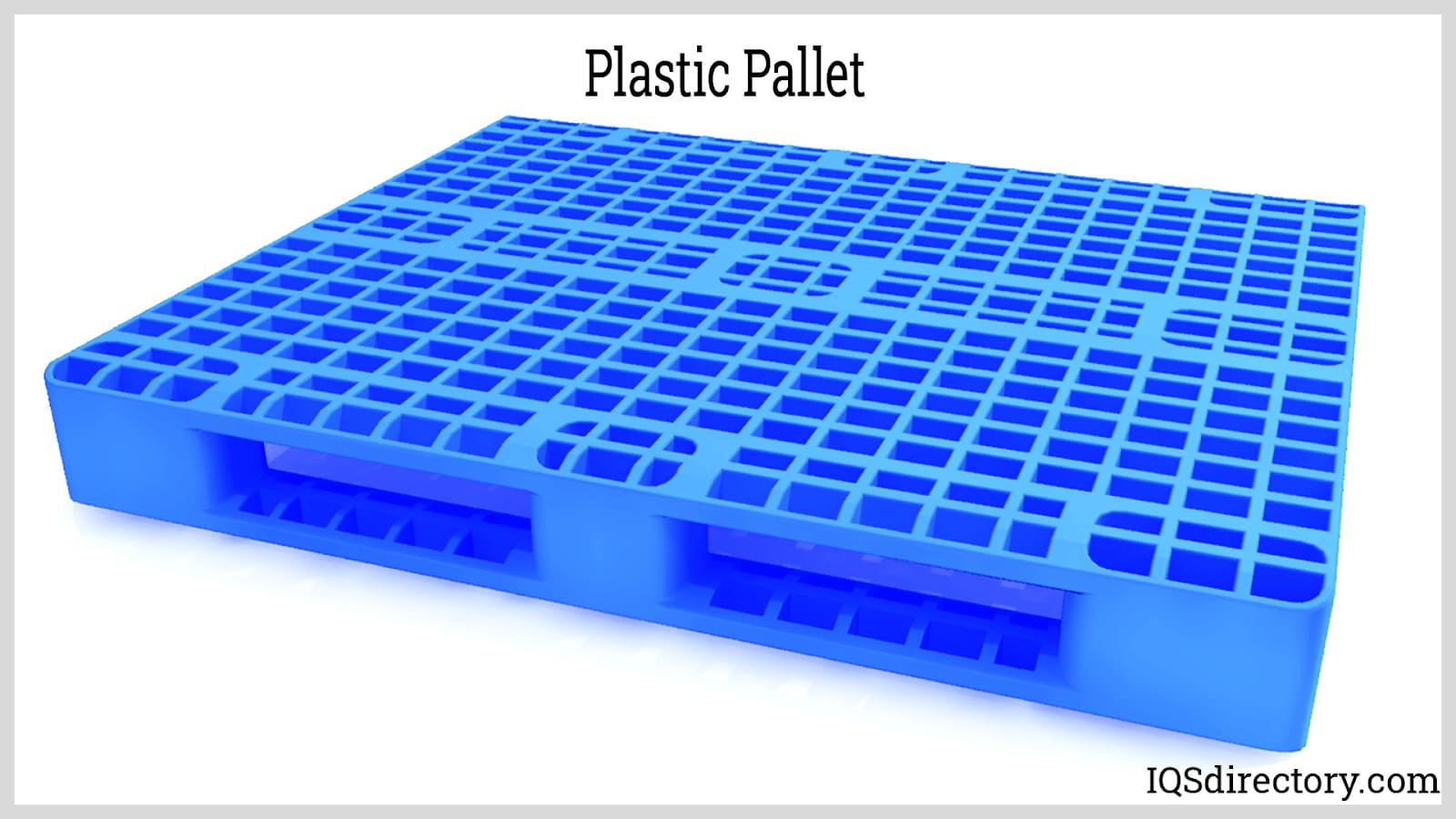

Recycled pallets refer to flat transport structures made from recycled plastic materials. They are used to support goods stably as they are carried from one point to another using a forklift, pallet jack, front loader, jacking device, or crane. Recycled pallets are usually made of strong plastic or wooden material that can withstand very strong weights without faulting. Read More…

TMF Corporation manufactures and supplies the Protech 4048 heavy duty plastic pallet. With inventory on hand, we have the ability quickly deliver and pallets we have in stock, including the FM approved Protech 4048 with color options, four-way entry and more.

At Premier Handling Solutions, we provide warehouse equipment solutions that improve overall productivity, safety and speed throughout the manufacturing, warehousing, distribution, consumption, storage and disposal process. Browse our selection of pallets, inverters, tippers, wire containers, and pallet dispensers to find the perfect product for your application.

At CTC Plastics, we specialize in designing and manufacturing high-quality plastic pallets, providing innovative solutions that meet the diverse needs of industries worldwide. With a commitment to sustainability, durability, and performance, we have built a reputation for delivering products that stand up to the toughest challenges in material handling.

At Monoflo International, we take pride in designing and manufacturing innovative plastic pallets that deliver exceptional performance for a wide range of industries. We focus on creating solutions that improve efficiency, durability, and sustainability in material handling and logistics.

Robinson Industries reduces operational costs and worker injuries through providing superior-quality plastic pallets. We sell pallets in a variety of sizes and styles. Robinson Industries is ready and able to meet diverse industry needs.

More Recycled Pallet Manufacturers

How Recycled Pallets Function

Recycled pallets, often manufactured from durable recycled plastic or refurbished wood, play a vital role in the modern supply chain. These eco-friendly pallets are engineered to withstand substantial loads and repeated handling, making them ideal for logistics, warehousing, and transportation applications. Their robust construction allows for heavy goods to be moved safely across short and long distances without compromising pallet integrity.

When securing products for transport, especially in high-volume industrial or commercial settings, a strong rope or stretch wrap is often used to fasten goods to the pallet. This ensures cargo stability and prevents items from shifting or falling during transit, which is crucial for both safety and efficiency in storage and shipping.

Handling recycled pallets is streamlined by the design of their base, which features accessible openings for forklift tines or pallet jack blades. Forklifts, equipped with extended blades, can insert their forks through these openings to lift and maneuver pallets from either side, optimizing workflow and reducing manual labor.

For smaller-scale or manual operations, pallet jacks serve as practical alternatives to forklifts. These manual or electric devices function similarly to a wheelbarrow, allowing operators to move pallets efficiently within warehouses, retail environments, or distribution centers.

Did you know? Choosing the right pallet handling equipment can improve warehouse safety and productivity. Explore common pallet applications and equipment choices below.

How Recycled Pallets Are Made

The process of manufacturing recycled plastic pallets or recycled wood pallets starts at a recycling center, where post-consumer and post-industrial plastics or wooden pallets are collected. The steps for recycled plastic pallet production typically include:

- Collection & Sorting: Plastics are sourced from various supply streams, sorted by type, and cleaned to remove contaminants.

- Shredding: Cleaned plastics are processed through industrial shredders, converting them into small chips or granules.

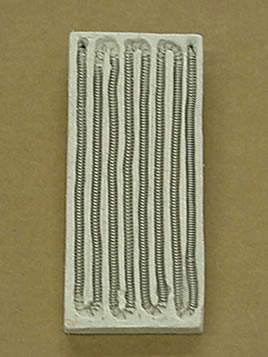

- Melting & Molding: The plastic granules are then heated until molten and injected or pressed into molds designed for specific pallet sizes and styles.

- Cooling & Finishing: Once molded, pallets are cooled, ejected, and undergo finishing processes such as branding, de-flashing (removing excess plastic), and quality inspections to meet regulatory and industry standards.

For recycled wooden pallets, the process often involves collecting used or broken pallets, repairing damaged boards, and replacing missing components. After restoration, the pallets are inspected and sanitized, making them suitable for reuse in various industries.

Looking to reduce your environmental footprint? Recycled pallets help companies meet sustainability goals by diverting waste from landfills and reducing reliance on virgin materials. Learn more about their environmental and cost-saving advantages below.

Types of Recycled Pallets

When selecting pallets for shipping, storage, or export, it’s essential to understand the various types of recycled pallets available. The most common recycled pallet types include:

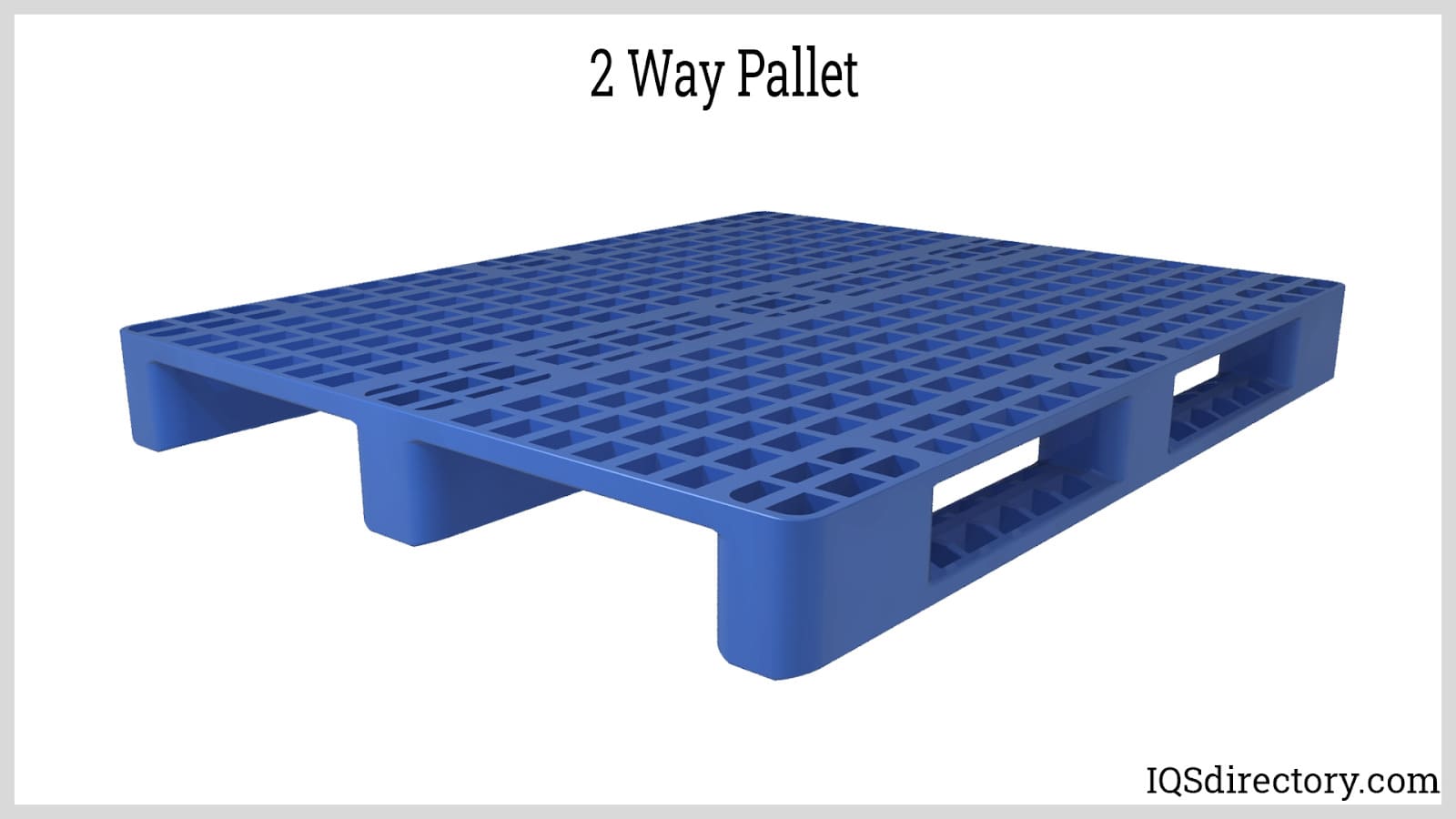

Two-Way Entry Pallet

Two-way entry pallets have forklift openings on two opposite sides, allowing lifting and movement from either the front or rear. These pallets are particularly suitable for operations with predictable pallet flow and where maximum strength is required, such as in heavy-duty industrial settings or bulk storage applications.

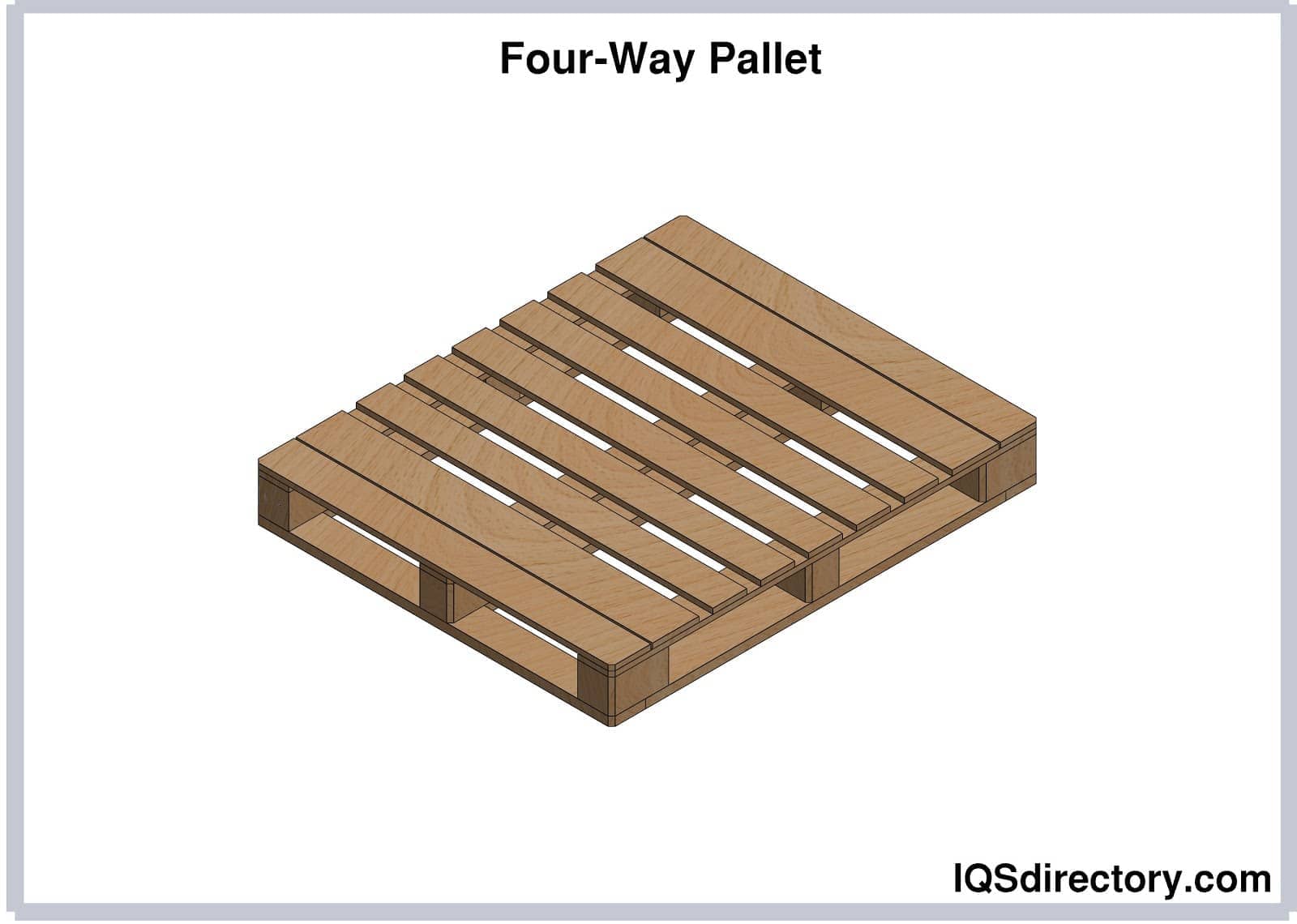

Four-Way Entry Pallet

Four-way entry pallets feature accessible notches or block designs on all four sides, enabling forklifts or pallet jacks to lift from any direction. This design increases flexibility and efficiency, especially in high-density warehouses and during rapid loading/unloading at distribution hubs. While they may offer slightly lower weight capacity compared to two-way pallets, their maneuverability makes them ideal for dynamic logistics environments.

Open Deck Pallet

Open deck pallets are engineered with strategically spaced deck boards, minimizing material use and reducing overall weight. The resulting gaps make these pallets lightweight and cost-effective, perfect for transporting large, uniform goods that won’t slip through the spaces. However, they are not recommended for small or irregularly shaped items.

Solid Deck Pallet

Solid deck pallets are manufactured from a continuous, gap-free surface—often a single molded piece of plastic. This seamless design prevents small products from falling through and simplifies cleaning, making them a top choice for industries with strict hygiene requirements, such as pharmaceuticals, food processing, and cleanroom environments.

Double Face Pallet

Double face pallets are constructed with both a top and bottom deck, distributing weight evenly and improving stability under heavy loads. This design enhances durability and stackability, making these pallets popular in applications where load balance and protection are critical—such as in export shipping, manufacturing, and large-scale warehousing.

Additional Recycled Pallet Types and Specializations

In addition to the standard designs, recycled pallets are also available in a range of custom options to meet specific industry or regulatory requirements. Popular specializations include:

- Nestable Pallets: Designed to stack inside each other when empty, maximizing warehouse storage space and minimizing return freight costs.

- Rackable Pallets: Engineered for use in pallet racks, providing enhanced rigidity and compatibility with automated material handling systems.

- Export Pallets: ISPM 15 exempt plastic pallets for hassle-free international shipping, eliminating the need for fumigation or heat treatment.

- Eco-Friendly Pallets: Made entirely from post-consumer recycled plastics, these pallets support circular economy initiatives and sustainable supply chain practices.

Which recycled pallet design fits your needs? Connect with leading recycled pallet suppliers for expert guidance on pallet selection, customization, and compliance.

Applications and Benefits of Recycled Pallets

Recycled pallets are rapidly gaining popularity across diverse sectors due to their versatility, sustainability, and cost-effectiveness. Companies seeking to optimize their supply chain, reduce operational costs, and meet environmental targets increasingly turn to recycled wood and plastic pallets. Here’s how they’re used and the key advantages they offer:

Common Applications of Recycled Pallets

- Warehousing & Distribution: Streamline storage, picking, and inventory management by providing a stable platform for goods, improving efficiency in high-volume logistics centers.

- Manufacturing: Facilitate movement of raw materials, semi-finished goods, and finished products within factories, supporting lean manufacturing and just-in-time processes.

- Retail & Merchandising: Serve as both transport and display solutions for commercial products, enabling quick restocking and attractive in-store product presentation.

- Export & International Shipping: ISPM 15-compliant recycled plastic pallets offer reliable, pest-free solutions for cross-border shipments, reducing regulatory hurdles.

- Pharmaceutical & Food Industries: Ensure hygienic handling of sensitive products, thanks to the easy-to-clean and non-porous properties of recycled plastic pallets.

- Military & Government Logistics: Used for secure, lightweight transport of equipment, supplies, and even vehicles—particularly in air drop scenarios where impact resistance is required.

- DIY and Upcycling Projects: Creative reuse of recycled pallets in furniture, gardening, and construction projects for sustainable design and cost savings.

Explore More: What are the best pallet options for food safety? How can recycled pallets support green building practices? Contact expert suppliers for tailored recommendations.

Benefits of Choosing Recycled Pallets

- Environmental Sustainability: By diverting waste materials from landfills and reducing reliance on virgin resources, recycled pallets support corporate sustainability goals and circular economy initiatives.

- Cost Savings: Manufacturing recycled pallets requires less energy and raw material input, resulting in lower acquisition costs and ongoing savings through repeat reuse and repair.

- Durability & Longevity: Recycled plastic pallets are highly resistant to moisture, pests, chemicals, and impact, ensuring a longer service life compared to traditional wood pallets.

- Hygiene & Safety: Non-porous surfaces are easy to sanitize, reducing risk of contamination in sensitive supply chains such as pharmaceuticals or food processing.

- Compliance: Many recycled plastic pallets are designed to meet global shipping standards, including ISPM 15 exemption, making them ideal for export and international logistics.

- Versatility & Flexibility: Available in a wide range of sizes, load capacities, and designs, recycled pallets can be tailored for light, medium, or heavy-duty use in nearly any industry.

- Reduced Carbon Footprint: Choosing recycled pallets helps lower greenhouse gas emissions associated with pallet manufacturing, transport, and disposal.

Did you know? Many leading brands now specify recycled pallets in their sustainability reports to demonstrate progress toward environmental, social, and governance (ESG) objectives.

Ready to switch to sustainable pallet solutions? Compare recycled pallet suppliers to find the most cost-effective and eco-friendly options for your business.

Decision Factors: How to Select Recycled Pallets for Your Business

Choosing the right recycled pallet is an important investment in your supply chain’s performance, safety, and sustainability. Consider the following criteria during the evaluation and purchasing process:

- Load Capacity: Determine the maximum weight the pallet must support, considering both static and dynamic loads.

- Size & Dimensions: Align pallet size with your storage systems, racking, and transportation modes (e.g., standard 48x40 inch, Euro pallet, custom sizes).

- Material Type: Decide between recycled plastic (ideal for hygiene and longevity) or recycled wood (cost-effective for certain applications).

- Handling Compatibility: Ensure the pallet design matches your equipment—forklifts, pallet jacks, conveyors, or automated guided vehicles (AGVs).

- Regulatory & Industry Requirements: Confirm compliance with standards like ISPM 15, FDA, or GMA where applicable.

- Environmental Goals: Prioritize suppliers that offer certified recycled content and can provide environmental impact documentation.

- Reusability & Repairability: Assess the ease of repairing or refurbishing the pallet for extended use.

- Supplier Reputation: Research supplier track record, customer reviews, and after-sales support.

Not sure which pallet best fits your application? Use our supplier directory and RFQ tools for expert recommendations and competitive price quotes.

Choosing the Right Recycled Pallet Supplier

With growing demand for sustainable packaging and logistics solutions, selecting a trusted recycled pallet supplier is essential. To ensure a successful purchasing experience, follow these best practices:

- Compare multiple recycled pallet companies using our comprehensive supplier directory.

- Review each supplier’s business profile for details on their experience, production capabilities, and quality certifications (such as ISO 9001, ISO 14001, or GRS).

- Utilize our proprietary website previewer to quickly understand each company’s specialties, product range, and customer focus.

- Request samples or case studies to evaluate pallet performance under real-world conditions.

- Use our streamlined RFQ form to request quotes from multiple recycled pallet companies in a single step.

- Ask about value-added services such as pallet recycling programs, custom branding, or on-site inventory management solutions.

Start your supplier search: Browse our directory of recycled pallet suppliers to find partners that align with your company’s sustainability, compliance, and operational needs.

Frequently Asked Questions:

- What is the difference between recycled wood and recycled plastic pallets? Recycled wood pallets are typically lower-cost and suitable for one-way shipping or heavy loads, while recycled plastic pallets offer superior hygiene, durability, and reusability.

- Are recycled pallets safe for food or pharmaceutical use? Yes, many recycled plastic pallets are manufactured to meet FDA or GMP standards, ensuring safety for sensitive products.

- How do I recycle used pallets? Most suppliers offer pallet recycling or buy-back programs—contact your supplier for details on collection and processing.

- What are the long-term cost savings of switching to recycled pallets? Although the upfront cost may be slightly higher than new wood pallets, recycled pallets deliver savings through extended lifespan, reduced repair costs, and lower disposal fees.

Ready to take the next step? Request quotes or contact suppliers directly for tailored solutions that match your application, budget, and sustainability goals.

55 Gallon Drums

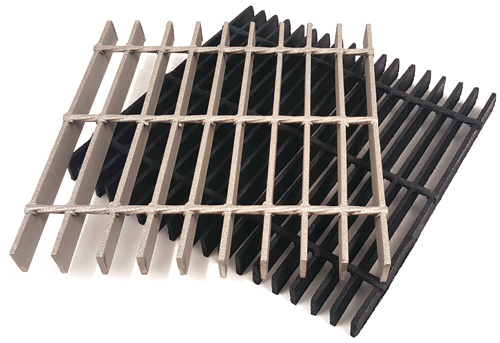

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches