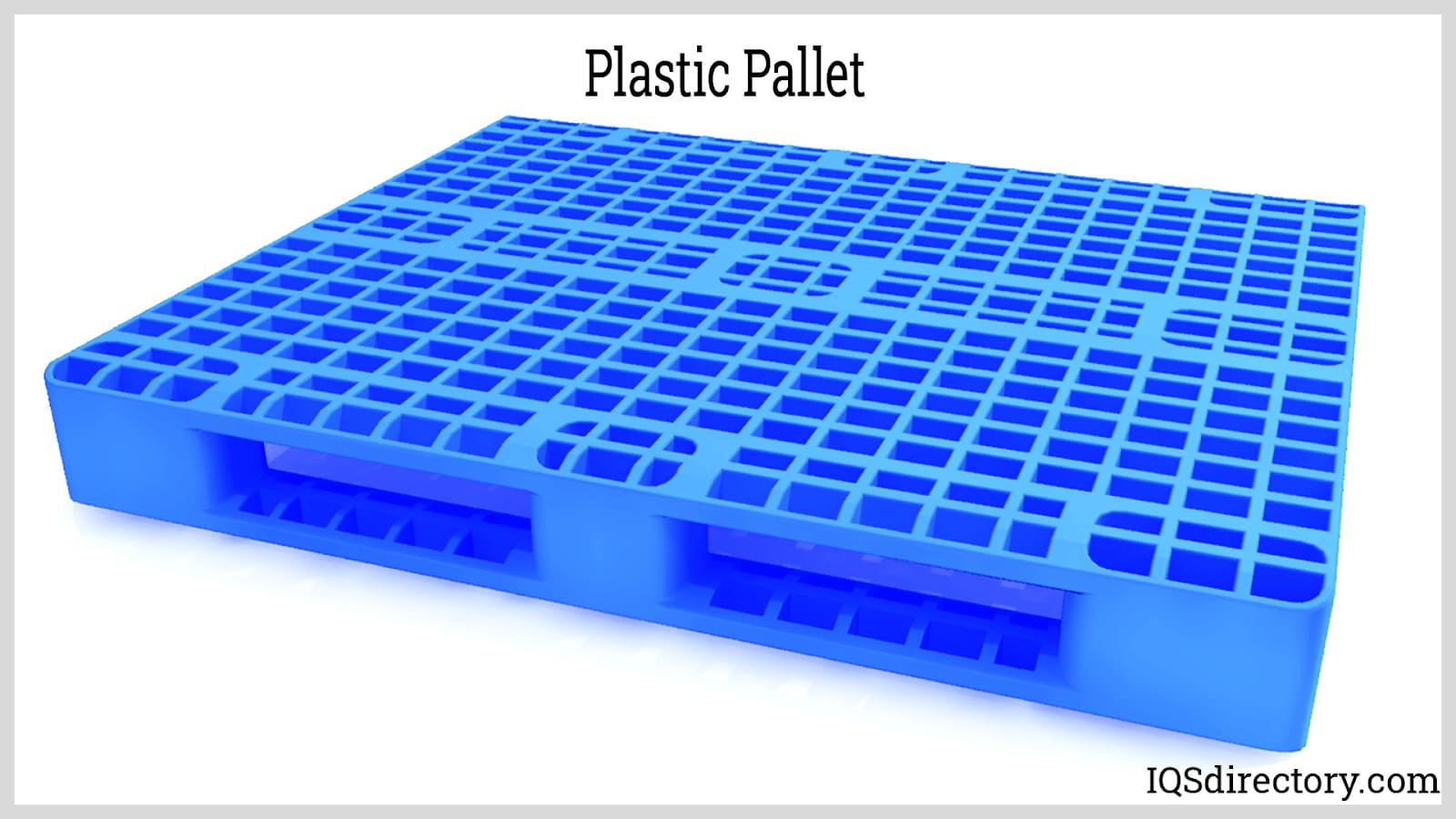

A used plastic pallet is a plastic pallet that has been used in transportation or storage applications but is still suitable for future use. Plastic pallets are reusable for a long time, depending on their application’s demand. Pallets are an indispensable commodity for any company that stores or transports products on an industrial scale. Read More…

TMF Corporation manufactures and supplies the Protech 4048 heavy duty plastic pallet. With inventory on hand, we have the ability quickly deliver and pallets we have in stock, including the FM approved Protech 4048 with color options, four-way entry and more.

At Premier Handling Solutions, we provide warehouse equipment solutions that improve overall productivity, safety and speed throughout the manufacturing, warehousing, distribution, consumption, storage and disposal process. Browse our selection of pallets, inverters, tippers, wire containers, and pallet dispensers to find the perfect product for your application.

At CTC Plastics, we specialize in designing and manufacturing high-quality plastic pallets, providing innovative solutions that meet the diverse needs of industries worldwide. With a commitment to sustainability, durability, and performance, we have built a reputation for delivering products that stand up to the toughest challenges in material handling.

At Monoflo International, we take pride in designing and manufacturing innovative plastic pallets that deliver exceptional performance for a wide range of industries. We focus on creating solutions that improve efficiency, durability, and sustainability in material handling and logistics.

Robinson Industries reduces operational costs and worker injuries through providing superior-quality plastic pallets. We sell pallets in a variety of sizes and styles. Robinson Industries is ready and able to meet diverse industry needs.

More Used Plastic Pallet Manufacturers

Comprehensive Guide to Used Plastic Pallets: Types, Manufacturing, Benefits & Supplier Selection

In today's fast-paced logistics, warehousing, and transportation industries, plastic pallets have become an indispensable component of supply chain management. The condition and quality of these pallets, as well as how they are handled, directly impact their reusability, load capacity, and cost-effectiveness. Understanding the advantages, types, manufacturing processes, and optimal sourcing strategies for used plastic pallets is crucial for businesses seeking to optimize operations, reduce expenses, and ensure safety and compliance.

Plastic pallets serve as rigid, stable platforms that provide mechanical support to large quantities of goods during handling, shipping, and storage. Their structural integrity safeguards products from damage during processes such as lifting, stacking, product storage, and long-distance transportation by sea, land, or air. To facilitate these activities, plastic pallets are engineered for compatibility with standard material handling equipment—including pallet jacks, forklifts, and front loaders—ensuring efficiency and safety throughout distribution centers and warehouses.

While pallets can be constructed from various materials such as wood, metal, or composite materials, plastic pallets offer unique advantages. They are prized for their durability, lightweight nature, hygienic surfaces, and resistance to contamination. These properties make used plastic pallets particularly attractive for industries where cleanliness, product integrity, and regulatory compliance are paramount, including food and beverage, pharmaceuticals, and electronics.

Plastic Pallets Manufacturing Processes

The manufacturing process plays a crucial role in determining the performance, longevity, and recyclability of plastic pallets. Leading plastic pallet manufacturers employ several molding and forming techniques, each tailored to specific load requirements, durability standards, and application environments. Understanding these manufacturing methods helps buyers select pallets that best fit their unique logistics and operational needs.

- Injection Molding: This is the most common process, where molten plastic is injected under high pressure into a custom mold. Injection-molded plastic pallets are known for their precision, strength, and consistent quality. These pallets are ideal for repeated use in automated systems and can support heavy dynamic and static loads.

- Structural Foam Molding: In this low-pressure process, an inert gas is added to the molten plastic, resulting in a cellular core surrounded by a rigid outer shell. Structural foam-molded pallets are lightweight yet strong, offering excellent impact resistance and reduced material usage—making them both economical and sustainable.

- Rotational Molding: Rotomolded pallets are formed by placing plastic resin into a mold, which is then heated and rotated on multiple axes. The result is a seamless, one-piece pallet that is highly durable and suitable for demanding environments, including chemical processing plants and pharmaceutical manufacturing.

- Thermoforming: Thermoformed plastic pallets are created by heating plastic sheets until pliable, then stretching or pressing them over a mold. This method is cost-effective for producing lightweight, nestable, and rackable pallets, often used for export shipping or one-way transportation.

Are you curious about which plastic pallet manufacturing process is best for your industry or supply chain? Explore our in-depth articles on pallet design optimization and compare the durability, cost, and environmental impact of each method.

Types of Plastic Pallets

Selecting the right plastic pallet type is essential for optimizing storage, handling, and transportation efficiency. Plastic pallets are classified according to their deck support structure and forklift entry design. The main categories include stringer pallets, block pallets, two-way entry pallets, and four-way entry pallets. Each type offers distinct benefits for different logistics scenarios and warehouse layouts.

Stringer Plastic Pallet

The stringer plastic pallet features a top deck supported by longitudinal, parallel slabs known as stringers. These stringers run along the pallet’s edges and center, providing stability and strength for medium-duty loads. Stringer pallets are often used in warehouses with standardized racking systems.

- Common Uses: Manufacturing, distribution centers, retail storage.

- Advantages: Simplicity in design, affordability, easy replacement of damaged stringers (in some models).

Block Plastic Pallet

Block plastic pallets use columnar posts (blocks) to support the top deck. These blocks are strategically positioned at the corners, center edges, and the center of the pallet, ensuring even weight distribution and exceptional load-bearing capacity. Block pallets typically allow for four-way forklift and pallet jack entry, maximizing maneuverability in busy warehouse environments.

- Common Uses: Automated warehouses, export and import shipping, high-throughput logistics.

- Advantages: Superior strength, versatility, enhanced handling efficiency, compatibility with both forklifts and pallet jacks.

Two-Way Plastic Pallet

The two-way plastic pallet is designed with entry points on only two opposite sides. This design requires handling equipment to approach the pallet at a specific angle, which can affect workflow flexibility. Traditionally, unmodified stringer pallets are two-way entry, but modifications—such as notching—can convert them into four-way entry pallets in wooden versions. In plastic pallets, however, such modifications are typically impractical due to structural integrity concerns.

- Common Uses: Bulk storage, non-racked warehouse environments, cost-sensitive applications.

- Advantages: Lower manufacturing costs, simplicity, suitable for applications where pallet orientation can be controlled.

- Decision Factor: Is a two-way or four-way pallet better for your warehouse layout? Assess your handling equipment, aisle width, and turnaround requirements before choosing.

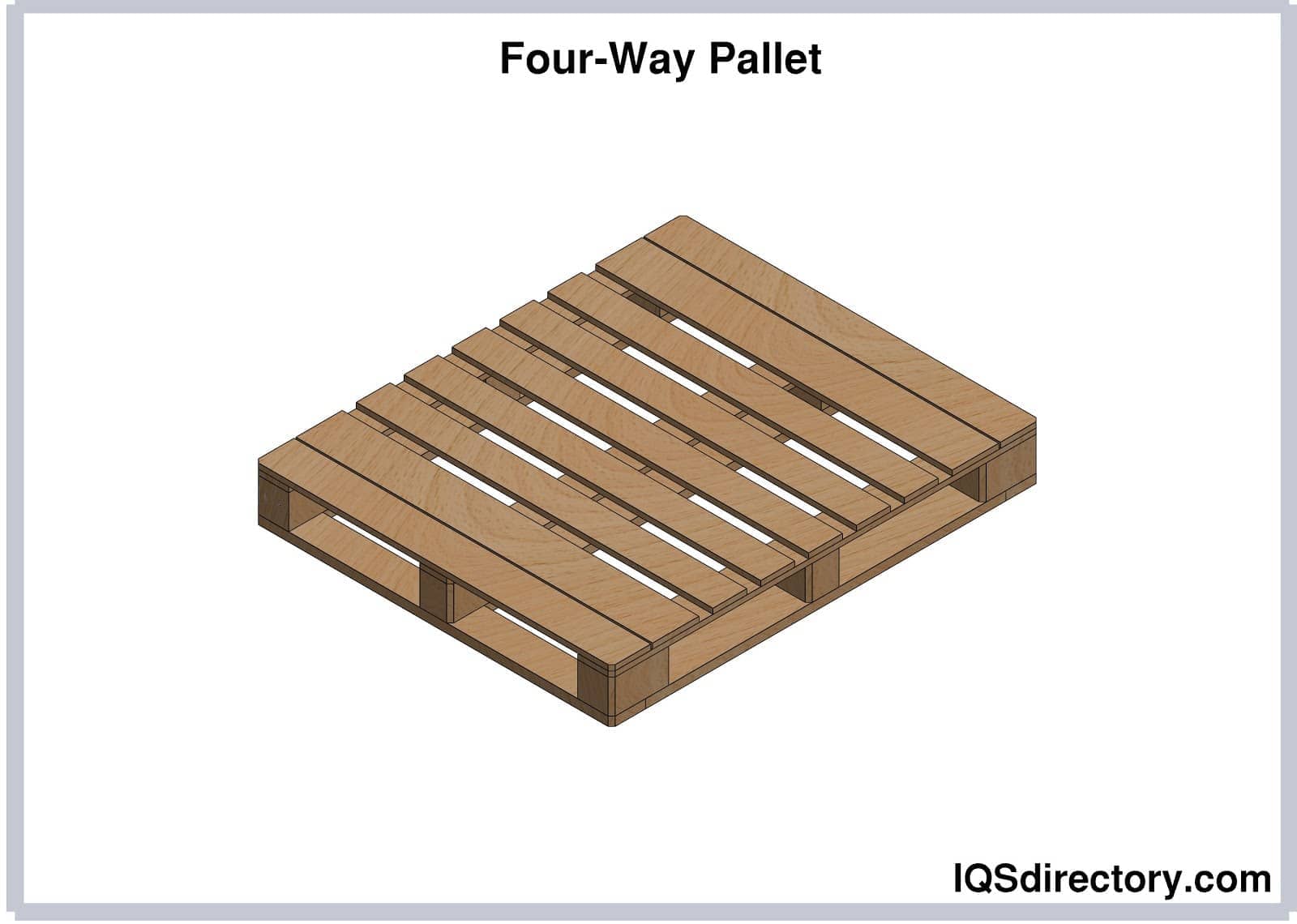

Four-Way Plastic Pallet

Four-way plastic pallets offer entry on all four sides, allowing maximum flexibility and efficiency during loading, unloading, and storage. This design is especially advantageous in environments with limited floor space or where rapid pallet access is essential. Most block pallets are inherently four-way entry.

- Common Uses: High-density storage, automated material handling systems, international shipping.

- Advantages: Reduced handling time, improved workflow, increased safety, and adaptability to various warehouse configurations.

Applications and Uses of Used Plastic Pallets

Used plastic pallets play a vital role across a range of industries due to their cost savings, environmental benefits, and reliable performance. While new plastic pallets offer pristine condition and longer lifespans, used pallets are a sustainable and budget-friendly alternative for many applications, including:

- Export and Import Shipping: Used plastic pallets are ideal for one-way or returnable shipments, providing a hygienic, ISPM 15-exempt (no fumigation required) solution for global logistics. Their consistent dimensions and lightweight design reduce shipping costs and simplify customs compliance.

- Retail and Product Display: In merchandising and retail environments, plastic pallets protect goods from floor contact and facilitate easy movement of bulk displays while minimizing product damage and improving store efficiency.

- Food & Beverage Industry: Plastic pallets are essential in food-grade and beverage processing facilities, where sanitation, resistance to moisture, and ease of cleaning are critical. They help maintain HACCP and FDA compliance, reducing contamination risks.

- Pharmaceutical & Healthcare: Used plastic pallets are widely used in pharmaceutical warehouses, laboratories, and hospitals for their hygienic surfaces, chemical resistance, and compliance with regulatory standards.

- Automotive & Industrial Manufacturing: Robust, reusable plastic pallets support the transport and storage of heavy components, tools, and parts in manufacturing plants, while minimizing workplace injuries by reducing splinters and sharp edges.

- Agriculture & Horticulture: Plastic pallets are used for transporting produce, nursery products, and gardening supplies, offering resistance to weather, pests, and decay.

- Warehousing & Distribution Centers: Used plastic pallets are a cost-effective solution for non-critical storage, overflow inventory, and high-turnover goods in large distribution hubs.

Looking to reduce your operational costs and environmental footprint? Learn more about sustainable supply chain strategies using recycled and refurbished plastic pallets.

Key Benefits of Used Plastic Pallets

Companies evaluating material handling solutions often compare used plastic pallets with wooden, metal, or new plastic pallets. Consider these compelling advantages of choosing used plastic pallets for your operations:

- Cost Savings: Used plastic pallets are significantly more affordable than new pallets, providing substantial cost reductions for businesses with large-scale shipping or storage needs.

- Eco-Friendly & Sustainable: Reusing plastic pallets reduces waste, supports circular economy initiatives, and minimizes your carbon footprint compared to single-use or disposable alternatives.

- Durability & Longevity: Even after multiple cycles, quality used plastic pallets maintain their structural integrity, delivering a longer service life than most wooden pallets.

- Consistent Specifications: Plastic pallets are manufactured to precise dimensions, ensuring compatibility with automated warehousing systems, racking, and conveyors.

- Hygienic & Easy to Clean: The non-porous surface of plastic pallets repels moisture, bacteria, and pests, making them ideal for food processing, pharmaceuticals, and other sensitive industries.

- Lightweight & Ergonomic: Reduced pallet weight translates to lower shipping costs and easier manual handling, supporting workplace safety initiatives.

- Resistant to Chemicals, Corrosion, and Pests: Plastic pallets are unaffected by most acids, alkalis, and insects, extending their useful lifespan and reducing maintenance requirements.

- Compliance: Used plastic pallets can be sourced to meet international standards (such as ISO, FDA, GMA, and HACCP) for export, food safety, and pharmaceuticals.

Wondering how used plastic pallets compare to wood or metal? Explore our comparison guides to help you make an informed decision based on your industry, budget, and operational needs.

Factors to Consider When Choosing Used Plastic Pallets

Selecting the best used plastic pallet involves evaluating a variety of decision factors, including intended use, load requirements, and environmental conditions. Keep these criteria in mind to ensure you invest in the right pallet solution for your business:

- Load Capacity: Determine your dynamic (in-motion) and static (at rest) load requirements. Heavier loads may require reinforced or block-style pallets.

- Dimensions & Compatibility: Ensure the pallet size fits your racking systems, containers, and transportation vehicles. Popular sizes include 48x40, 1200x1000 mm, and others.

- Rackability & Stackability: Choose rackable pallets for supported storage and stackable models for space-saving during return shipments or storage.

- Hygiene & Cleanliness: For food, beverage, or pharmaceutical use, verify that pallets can be sanitized and meet relevant regulatory standards.

- Material Type: HDPE (High-Density Polyethylene) and PP (Polypropylene) are common, each offering unique benefits in terms of durability, temperature resistance, and chemical compatibility.

- Environmental Resistance: Assess whether your pallets will be exposed to moisture, UV radiation, chemicals, or extreme temperatures.

- Regulatory Compliance: Confirm that your pallets comply with international shipping and food safety standards.

- Supplier Reputation: Source used plastic pallets from reputable suppliers who inspect, refurbish, and grade their inventory for quality and safety.

Need help determining the right pallet for your environment? Contact our pallet experts or use our decision tools to match your operational demands with the best used plastic pallet solution.

How to Choose the Right Used Plastic Pallet Supplier

Ensuring a positive outcome in your search for used plastic pallets starts with partnering with a reputable supplier. The right supplier can offer high-quality, certified pallets that meet your specific application requirements, provide competitive pricing, and deliver excellent customer support. Follow these steps to make an informed supplier selection:

- Research & Compare: Utilize our directory of used plastic pallet suppliers to compare companies based on their areas of expertise, available inventory, and customer reviews.

- Assess Quality Control: Choose suppliers who inspect, clean, and refurbish pallets to ensure safety, reliability, and compliance with industry standards.

- Request Detailed Specifications: Ask for load ratings, material types, and photos or samples to verify pallet quality before purchase.

- Check Service Options: Look for value-added services such as bulk purchasing, pallet recycling, leasing programs, and just-in-time delivery.

- Leverage Online Tools: Use our patented website previewer to quickly learn about each supplier’s specialization, and our RFQ (Request for Quote) form to contact multiple companies with a single inquiry.

- Evaluate Sustainability Practices: Consider suppliers who promote recycling, upcycling, and environmentally responsible sourcing.

Ready to request a quote or compare suppliers? Visit our supplier directory and connect with trusted used plastic pallet providers today!

Frequently Asked Questions About Used Plastic Pallets

- What are the main differences between used and new plastic pallets?

Used pallets are more affordable and environmentally friendly, while new pallets offer longer lifespans and pristine condition. Both provide excellent hygiene and durability. - Are used plastic pallets safe for food and pharmaceuticals?

Yes—provided they are cleaned, inspected, and certified by reputable suppliers, used plastic pallets are suitable for hygienic applications. - Can plastic pallets be recycled?

Absolutely. Most plastic pallets are made from recyclable polymers such as HDPE and PP, contributing to circular economy initiatives and reducing landfill waste. - How do I determine the right size and type of plastic pallet for my needs?

Consider your load requirements, racking systems, industry regulations, and handling equipment to select the optimal pallet type and dimensions. - What is the lifespan of a used plastic pallet?

While service life depends on application and handling, quality used plastic pallets can often last for several years with proper care and maintenance.

Conclusion: Unlock the Value of Used Plastic Pallets

Used plastic pallets are a smart, sustainable, and cost-effective solution for businesses seeking to enhance logistics, ensure product safety, and reduce environmental impact. By understanding the different types, manufacturing processes, and key benefits, you can make an informed decision that aligns with your operational goals and budget. Leverage our supplier directory and expert resources to source high-quality used plastic pallets, streamline your supply chain, and drive long-term value for your organization.

Have more questions? Discover our complete resource library or contact our experts for personalized recommendations on selecting, sourcing, and optimizing plastic pallets for your business.

55 Gallon Drums

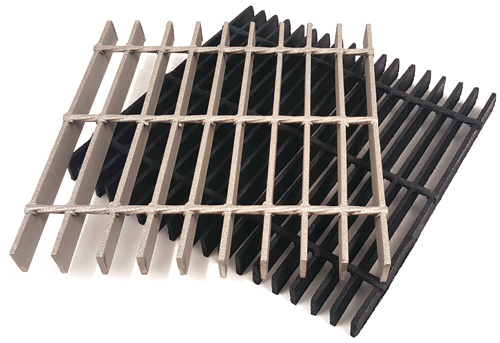

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches